Introduction

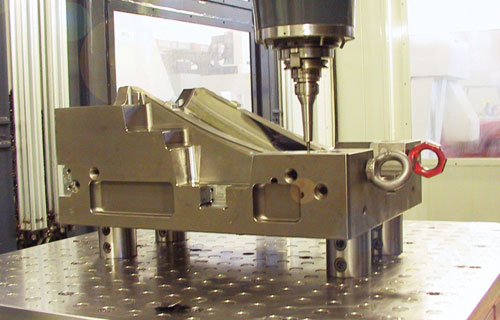

In CNC machining, most discussions focus on cutting tools, spindle speeds, or advanced software. Yet one of the most overlooked elements of productivity is the workholding system. Without reliable and efficient fixtures, the best machine and the sharpest tool cannot perform to their potential.

This article explores why workholding is the backbone of productivity, how advanced solutions improve efficiency, and why shops must rethink their fixture strategies.

The Productivity Equation

Productivity in CNC shops comes down to three factors:

- Machine utilization (spindle cutting vs. idle time)

- Setup time (loading, aligning, clamping)

- Scrap rate (wasted materials due to errors)

Workholding impacts all three. Poor fixtures mean long setups, frequent downtime, and inconsistent parts.

How Workholding Drives Efficiency

- Reduced Setup Time – hydraulic vise and zero point clamps cut setup from 30 minutes to under 5 minutes.

- Higher Repeatability – Fixtures with micron-level accuracy ensure part-to-part consistency.

- Automation Compatibility – Workholding designed for robotics supports lights-out manufacturing.

- Flexibility – Modular systems enable rapid response to changing orders.

Real-World Impact

- A shop producing aerospace brackets reduced setup times by 70% after upgrading to zero point systems.

- An automotive supplier cut scrap by 50% with self centering vise .

Conclusion

Workholding is not a support function—it is a productivity multiplier. Modern CNC shops that invest in advanced systems gain speed, consistency, and profitability.